As the demand for high-quality gloves continues to grow, traditional manual inspection methods struggle to meet rising customer expectations. Complaints about surface defects, such as tears, oil stains, and excess material, have become increasingly common.

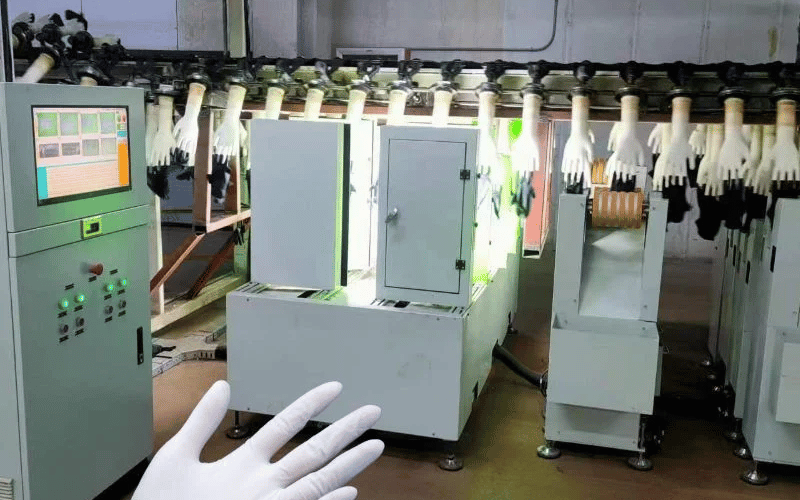

To address these challenges, our company has developed an advanced automated glove visual inspection system. This cutting-edge solution leverages high-resolution cameras, intelligent algorithms, and real-time defect detection to ensure consistent quality, reduce labor costs, and enhance customer satisfaction. By integrating automation into the inspection process, glove manufacturers can achieve unparalleled efficiency and reliability in their production lines.

Understanding Glove Inspection Systems

What is a Glove Inspection System?

A glove inspection system is an automated solution designed to detect defects in gloves during the production process. These systems use advanced technologies, such as cameras and sensors, to identify issues like tears, oil stains, black spots, and other imperfections. By automating the inspection process, manufacturers can ensure consistent quality, reduce waste, and improve overall efficiency.

Unlike manual inspection, which is prone to human error, glove inspection systems provide precise and reliable results. They are particularly useful in high-volume production lines where speed and accuracy are critical. These systems can be customized to meet specific production requirements, such as detecting defects of a certain size or inspecting gloves of various colors and materials.

Importance of Visual Inspection in Glove Production

Visual inspection plays a crucial role in maintaining the quality and safety of gloves, especially in industries like healthcare, food processing, and manufacturing. Defective gloves can compromise safety, lead to contamination, or fail to meet regulatory standards. Automated visual inspection ensures that only high-quality gloves reach the market.

Key benefits of visual inspection include:

- Consistency: Automated systems maintain uniform inspection standards, eliminating variability caused by human fatigue or bias.

- Efficiency: High-speed cameras and algorithms can inspect thousands of gloves per hour, significantly reducing production bottlenecks.

- Cost Savings: By identifying defects early, manufacturers can minimize waste and avoid costly recalls or customer complaints.

Visual inspection systems are particularly effective in detecting defects that are difficult to spot manually, such as small tears or subtle discolorations. This ensures that gloves meet stringent quality standards before they are packaged and shipped.

Key Components of a Vision System for Inspection

A vision system for glove inspection typically consists of several key components, each playing a vital role in the detection process:

-

Cameras: High-resolution cameras capture detailed images of gloves as they move along the production line. Multiple cameras may be used to inspect different angles and areas, such as the palm, fingers, and cuffs.

-

Lighting: Proper lighting is essential for accurate defect detection. LED lights are commonly used to illuminate gloves evenly, reducing shadows and enhancing visibility of defects like oil stains or black spots.

-

Software Algorithms: Advanced algorithms analyze the images captured by the cameras to identify defects. These algorithms use techniques like deep learning and pattern recognition to detect issues with high precision.

-

Sensors: Sensors monitor the position and movement of gloves on the production line, ensuring that each glove is inspected thoroughly. They also help synchronize the cameras and lighting with the production speed.

-

User Interface: A user-friendly interface allows operators to monitor the inspection process, adjust settings, and review defect data. This ensures that the system can be easily managed and optimized for different production needs.

By integrating these components, a vision system can deliver accurate, real-time inspection results, helping manufacturers maintain high-quality standards and improve operational efficiency.

Advantages of the Glove Online Visual Inspection System

- High-resolution industrial cameras and lenses paired with high-brightness stroboscopic lighting ensure precise imaging.

- High-performance computing architecture and proprietary visual inspection algorithms provide flexible and reliable operation with adjustable detection precision.

- Online automatic identification and rejection, capable of integrated control with other Ruibang automation products to prevent defective gloves from entering the packaging process.

Online Visual Inspection System for Nitrile Gloves

| Name | Defect coverage rate | Inspection rate of serious defects | Detection rate | Misjudgment rate | Note |

| Double former production line 16-camera programme Palm + Supporting mouth + droop |

99% | ≤40PPM | >98% | <0.5% | WSL’s independent research and development is entirely independent, with intellectual property rights to the software |

| 1. Critical Defect Detection Rate = Number of critical defects detected per unit time / Actual critical defect quantity × 100% 2. Major Defect Detection Rate = Number of major defects detected per unit time / Actual major defect quantity × 100% 3. False Positive Rate = Number of qualified items picked per unit time / Total output per unit time × 100% 4. For nitrile gloves in colors other than black, reference the specifications for blue gloves. Black gloves are not tested for oil stains or residual material defects. |

|||||

| Notes: 1. Capable of detecting defects visible to operators within the inspection area, including tears, oil stains, and excess material. Under stable production conditions, rejection rates can be controlled at approximately 1% of glove output. Should production line abnormalities cause rejection rates to rise within a unit time, the equipment will trigger timely alarm notifications. 2. Capable of detecting impacts larger than 1mm in diameter and oil stains or dark spots exceeding 0.5mm in diameter within the inspection area. 3. Utilizes a combination of deep learning algorithms and visual simulation algorithms for analysis and calculation, achieving detection accuracy significantly higher than manual inspection. The size of detectable defects can be adjusted as needed. |

|||||

Online Visual Inspection System for PVC Gloves

| Name | Detection rate of oil stains, black spots and impurities | Detection rate | Misjudgment rate | Note |

| Single former glove production line, six camera solutions | 97% | >98% | <0.5% | WSL’s independent research and development is entirely independent, with intellectual property rights to the software |

| 1. Critical defect detection rate = Number of critical defects detected per unit time / Actual critical defect quantity × 100% 2. Major defect detection rate = Number of major defects detected per unit time / Actual major defect quantity × 100% 3. False detection rate = Number of qualified items picked per unit time / Total production per unit time × 100% (excluding interference from hand molds) 4. Inspection area: From the base of the palm fingers downward. 5. Since some black spots are rolled into the hem and cannot be photographed, black spots on the hem are excluded from inspection. |

||||

| Note: *① Capable of detecting easily identifiable light oil stains with a diameter of 5mm or larger within the inspection area, as well as darker oil stains and black spots with a diameter of 1mm or larger. (Inspection precision can be manually adjusted) Higher precision can be customized. *② The single-hand mold production line with a 6-camera solution can detect tears at the glove cuff and holes caused by the mold release machine’s gripper opening. |

||||

Defect Detection in Glove Manufacturing

Common Defects Found in Gloves

In glove manufacturing, defects can compromise product quality and safety, making it essential to identify and address them during production. Common defects include:

- Tears and Holes: These are structural issues that can render gloves unusable, especially in industries requiring high durability, like healthcare or manufacturing.

- Oil Stains and Black Spots: These visual imperfections often result from contamination during production and can affect the glove’s appearance and usability.

- Excess Material: Extra material at seams or fingertips can hinder functionality and create discomfort for users.

- Uneven Thickness: Variations in glove thickness can lead to weak spots, increasing the risk of tears during use.

- Improper Sizing: Gloves that are too tight or loose can fail to provide adequate protection or comfort.

Identifying these defects early ensures that only high-quality gloves reach the market, reducing waste and maintaining customer trust.

Techniques for Effective Defect Detection

Manufacturers use a combination of manual and automated techniques to detect defects in gloves. Effective methods include:

- Visual Inspection: Operators visually examine gloves for obvious defects like tears, stains, or uneven material. While this method is straightforward, it can be inconsistent due to human error or fatigue.

- Automated Vision Systems: High-resolution cameras and advanced algorithms analyze gloves for defects with precision. These systems can detect even minor issues, such as small black spots or subtle thickness variations, that might be missed manually.

- Pressure Testing: This technique involves inflating gloves to check for leaks or weak spots. It is particularly effective for detecting holes or tears that are not visible to the naked eye.

- Weight and Thickness Measurement: Automated systems measure the weight and thickness of gloves to ensure consistency and identify any deviations from production standards.

- UV Light Inspection: UV light can highlight certain defects, such as oil stains or contamination, that are not easily visible under normal lighting conditions.

By combining these techniques, manufacturers can achieve a comprehensive inspection process that ensures product quality and compliance with industry standards.

Role of Automation in Defect Detection

Automation has revolutionized defect detection in glove manufacturing, offering unparalleled speed, accuracy, and efficiency. Automated systems eliminate the inconsistencies of manual inspection and enable manufacturers to scale production without compromising quality.

Key benefits of automation include:

- Increased Accuracy: Automated systems use advanced algorithms to detect defects with high precision, reducing the risk of missed issues.

- Faster Inspection: High-speed cameras and sensors can inspect thousands of gloves per hour, keeping up with the demands of large-scale production.

- Cost Efficiency: By identifying defects early, automation minimizes waste and reduces the need for rework, saving time and resources.

- Real-Time Monitoring: Automated systems provide real-time data on defect rates and production quality, allowing manufacturers to address issues immediately.

- Customization: These systems can be tailored to detect specific defects or meet unique production requirements, ensuring flexibility and adaptability.

For example, a vision system equipped with deep learning algorithms can identify defects like small tears or black spots with remarkable accuracy. This ensures that gloves meet stringent quality standards, even in high-volume production environments. Automation not only improves defect detection but also enhances overall operational efficiency, making it an indispensable tool in modern glove manufacturing.

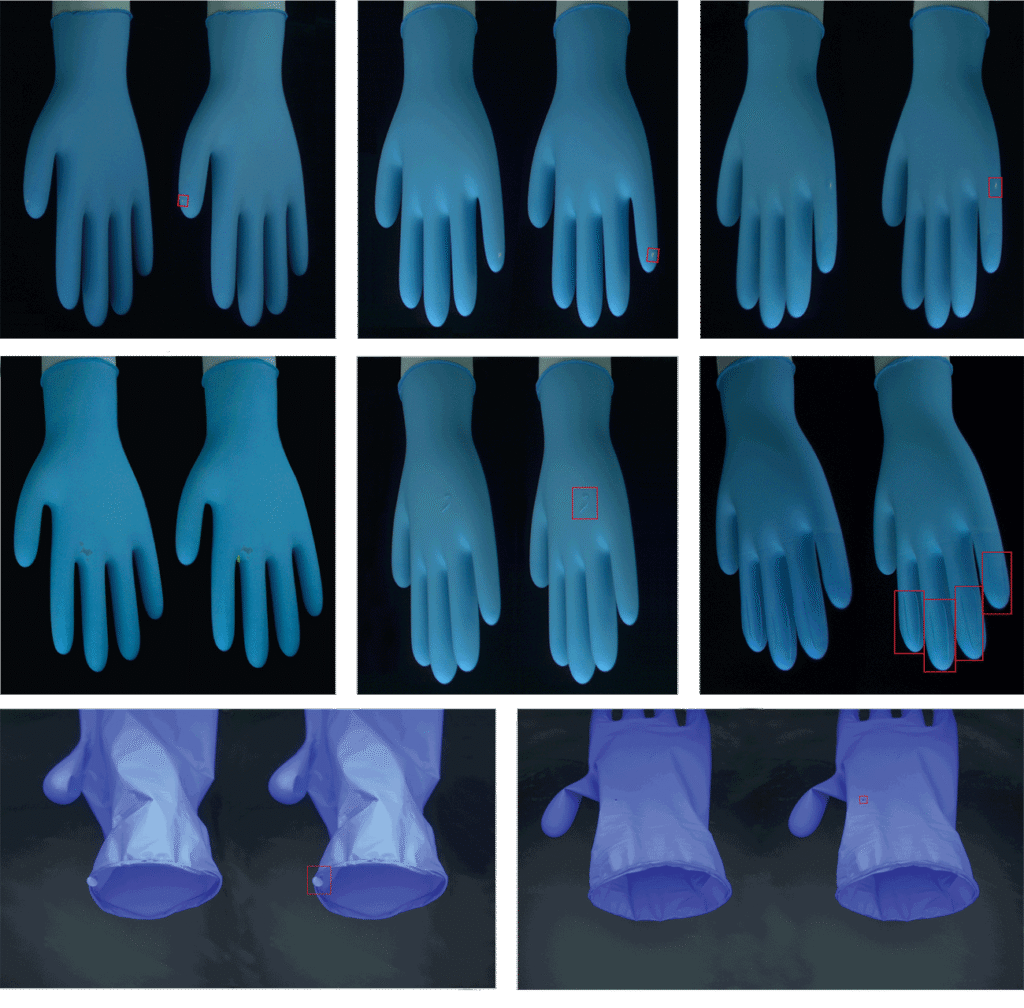

Defect Detection Diagram for Nitrile Gloves

Implementing a Visual Inspection System

Steps to Automate Glove Inspection

-

Analyze Current Inspection Challenges

- Actionable Tip: Document the most common defects (e.g., pinholes, stains, uneven thickness) and identify where manual inspection fails—such as missed defects or slow throughput.

- Example: If operators struggle to detect small black spots, note this as a priority for automation.

-

Define Measurable Goals

- Actionable Tip: Set specific targets, like reducing defect rates by 20%, doubling inspection speed, or achieving 99% defect detection accuracy.

- Example: “We aim to inspect 10,000 gloves per hour with a defect detection rate of 98% or higher.”

-

Select the Right Technology

- Actionable Tip: Choose high-resolution cameras for surface defects, infrared sensors for thickness variations, and AI algorithms for pattern recognition.

- Example: Use deep learning models trained on your specific defect dataset to detect subtle issues like micro-tears or discoloration.

- Pro Tip: Ensure the system integrates seamlessly with your existing production line and supports real-time defect alerts.

-

Conduct a Pilot Test

- Actionable Tip: Test the system on a single production line or batch. Adjust parameters like lighting angles, camera resolution, and defect thresholds.

- Example: If the system flags too many false positives, recalibrate the AI model to balance sensitivity and specificity.

- Pro Tip: Use diverse glove samples (e.g., different colors, materials, and defect types) to ensure robust performance.

-

Train Operators for Success

- Actionable Tip: Provide hands-on training on system operation, troubleshooting, and interpreting inspection data.

- Example: Teach operators how to adjust defect detection thresholds or replace faulty sensors without halting production.

- Pro Tip: Create a quick-reference guide or video tutorials for ongoing support.

-

Roll Out Gradually and Monitor Performance

- Actionable Tip: Scale up implementation line by line, monitoring key metrics like defect detection rates, false positives, and inspection speed.

- Example: Compare pre- and post-automation defect rates to measure ROI.

- Pro Tip: Schedule regular system maintenance and software updates to ensure long-term reliability.

Why It Matters

By automating glove inspection with precision, manufacturers can eliminate human error, improve product quality, and boost production efficiency. A well-implemented system not only reduces waste but also builds trust with customers by delivering consistently high-quality gloves.

Choosing the Right Vision System for Your Needs

Selecting the right vision system is critical to the success of your inspection process. Consider the following factors when making your choice:

- Inspection Requirements: Determine the types of defects you need to detect, such as tears, oil stains, or black spots. Select a system that can identify these issues with precision.

- Production Volume: High-speed production lines require systems that can inspect large quantities of gloves quickly without compromising accuracy.

- Customization Options: Look for systems that allow you to adjust settings, such as defect size thresholds or inspection area coverage, to meet your specific needs.

- Integration Capabilities: Ensure the system can integrate seamlessly with your existing production line and software, such as manufacturing execution systems (MES).

- Cost and ROI: Evaluate the system’s cost against its potential benefits, such as reduced waste, improved quality, and faster inspection times. A system with a higher upfront cost may offer better long-term savings.

For example, a production line handling gloves with intricate designs may benefit from a vision system equipped with advanced pattern recognition capabilities. Choosing the right system ensures efficient defect detection and enhances overall production quality.

Integrating Visual Inspection with Packaging Processes

Integrating visual inspection with packaging processes streamlines production and ensures that only high-quality gloves are packaged and shipped. Here’s how to achieve this integration:

- Synchronize Inspection and Packaging: Use sensors and software to link the inspection system with packaging equipment. This ensures that defective gloves are automatically removed before reaching the packaging stage.

- Real-Time Data Sharing: Enable the inspection system to share defect data with packaging machines. This allows for dynamic adjustments, such as pausing the line if defect rates exceed acceptable limits.

- Automated Sorting: Implement sorting mechanisms to separate defective gloves from acceptable ones. This reduces manual handling and ensures that only quality products are packaged.

- Quality Assurance Checks: Incorporate additional checks at the packaging stage to verify that no defective gloves have been missed. This adds an extra layer of quality control.

- Feedback Loops: Use data from the inspection system to identify recurring defects and address their root causes. This continuous improvement process enhances both inspection and packaging efficiency.

By integrating visual inspection with packaging, manufacturers can create a cohesive production process that minimizes waste, improves quality, and boosts overall efficiency.

Benefits of Automated Glove Inspection

Increased Efficiency and Accuracy

Automated glove inspection systems significantly enhance efficiency by processing large volumes of gloves in a fraction of the time required for manual inspection. High-speed cameras and advanced algorithms can inspect thousands of gloves per hour, ensuring that production keeps pace with demand.

These systems also deliver unmatched accuracy. Unlike manual inspection, which is prone to human error and fatigue, automated systems consistently detect even the most minor defects, such as tiny tears or subtle discolorations. This precision reduces the likelihood of defective products reaching customers, safeguarding your brand’s reputation.

For example, a system equipped with deep learning algorithms can identify patterns and anomalies with remarkable accuracy, ensuring that no defect goes unnoticed. This combination of speed and precision makes automation indispensable in modern glove manufacturing.

Cost-Effectiveness of Automated Systems

While the initial investment in automated inspection systems may seem high, the long-term cost savings make them a worthwhile investment. By identifying defects early in the production process, these systems minimize waste and reduce the need for rework, saving both time and resources.

Automated systems also lower labor costs by reducing reliance on manual inspection. Instead of employing multiple workers to inspect gloves, manufacturers can rely on a single system to handle the task efficiently. Additionally, the reduced error rate means fewer defective products are shipped, minimizing the risk of costly recalls or customer complaints.

For instance, a production line that integrates automated inspection can achieve higher throughput with fewer defects, leading to increased profitability and a faster return on investment.

Improving Product Quality through Consistent Inspection

Consistency is key to maintaining high product quality, and automated systems excel in this area. Unlike manual inspection, which can vary depending on the operator’s skill or fatigue level, automated systems apply the same rigorous standards to every glove.

These systems can be programmed to detect specific defects, such as oil stains, black spots, or uneven thickness, ensuring that only gloves meeting the highest quality standards are approved. This consistency not only improves customer satisfaction but also helps manufacturers comply with industry regulations and certifications.

For example, a vision system with customizable settings can adapt to different glove types and production requirements, ensuring that every product meets the desired specifications. By delivering consistent, high-quality results, automated inspection systems help manufacturers build trust and loyalty among their customers.

Frequently Asked Questions

Q: What is a glove visual inspection system?

A: A glove visual inspection system is an automated technology used in glove manufacturing to ensure quality control. It utilizes advanced vision systems to detect defects, including stains, leaks, tears, and other imperfections. By identifying faulty gloves early, this system ensures only high-quality products are packaged and delivered, enhancing production efficiency and product reliability.

Q: How does the glove inspection system improve defect detection?

A: The glove inspection system uses advanced algorithms and high-speed cameras to detect defects with precision. Automating the inspection process boosts accuracy and efficiency, identifying defective gloves that manual inspections might miss. This reduces waste and enhances product reliability.

Q: What types of defects can the vision inspection system identify?

A: The vision inspection system detects a variety of defects, including oil stains, tears, and leaks. With deep learning technology, it can identify even subtle flaws, ensuring only compliant gloves proceed to the packaging stage.

Q: Is the glove inspection process fully automated?

A: Yes, modern glove inspection systems are fully automated. They integrate into manufacturing lines, using conveyor systems to move gloves past high-speed cameras and detection software. This automation improves productivity and provides real-time alerts and adjustments to maintain quality standards.

Q: How does the accuracy of a visual inspection system affect production?

A: Accurate visual inspection systems directly enhance production efficiency. They prevent defective gloves from reaching the market, avoiding costly recalls and protecting brand reputation. High accuracy also reduces rework and streamlines the manufacturing process, boosting overall output.

Q: What role does software play in glove testing and inspection?

A: Software plays a vital role in glove testing by analyzing data from the vision system. It processes images, applies defect detection algorithms, and generates quality reports. This helps manufacturers track performance metrics and continuously improve inspection protocols.

Q: Can vision inspection systems be integrated with existing manufacturing processes?

A: Yes, vision inspection systems are highly adaptable and can integrate seamlessly into existing manufacturing lines. Whether through conveyor systems or standalone setups, they can be customized to meet specific production needs without causing significant disruptions.

Q: What advantages do automatic glove inspection systems offer over manual inspection?

A: Automatic glove inspection systems provide higher efficiency, improved detection accuracy, and lower labor costs compared to manual inspection. They ensure consistent quality checks, reduce human error, and increase production throughput, resulting in improved productivity and lower operational expenses.

Concluding Summary

Automated glove visual inspection systems have revolutionized the way manufacturers ensure product quality and consistency. By detecting defects with precision, these systems eliminate inconsistencies, reduce waste, and streamline production processes. With features such as real-time monitoring, customizable settings, and seamless integration into existing manufacturing lines, they provide a practical and cost-effective solution for meeting stringent quality standards. As customer expectations continue to rise, adopting automated inspection technology is no longer optional—it’s essential for maintaining competitiveness and delivering superior products.